Contact Us

From Electronics to Aerospace: Top 10 Graphite Sheet Uses

Graphite sheets are increasingly recognized for their unique properties and versatility, making them essential in various applications across different industries. Known for their excellent thermal and electrical conductivity, high mechanical strength, and chemical resistance, graphite sheets play a crucial role in advancing technology and improving performance. This comprehensive guide explores the top 10 uses of graphite sheets, highlighting their benefits and applications in electronics, energy, automotive, aerospace, and beyond.

What are Graphite Sheets?

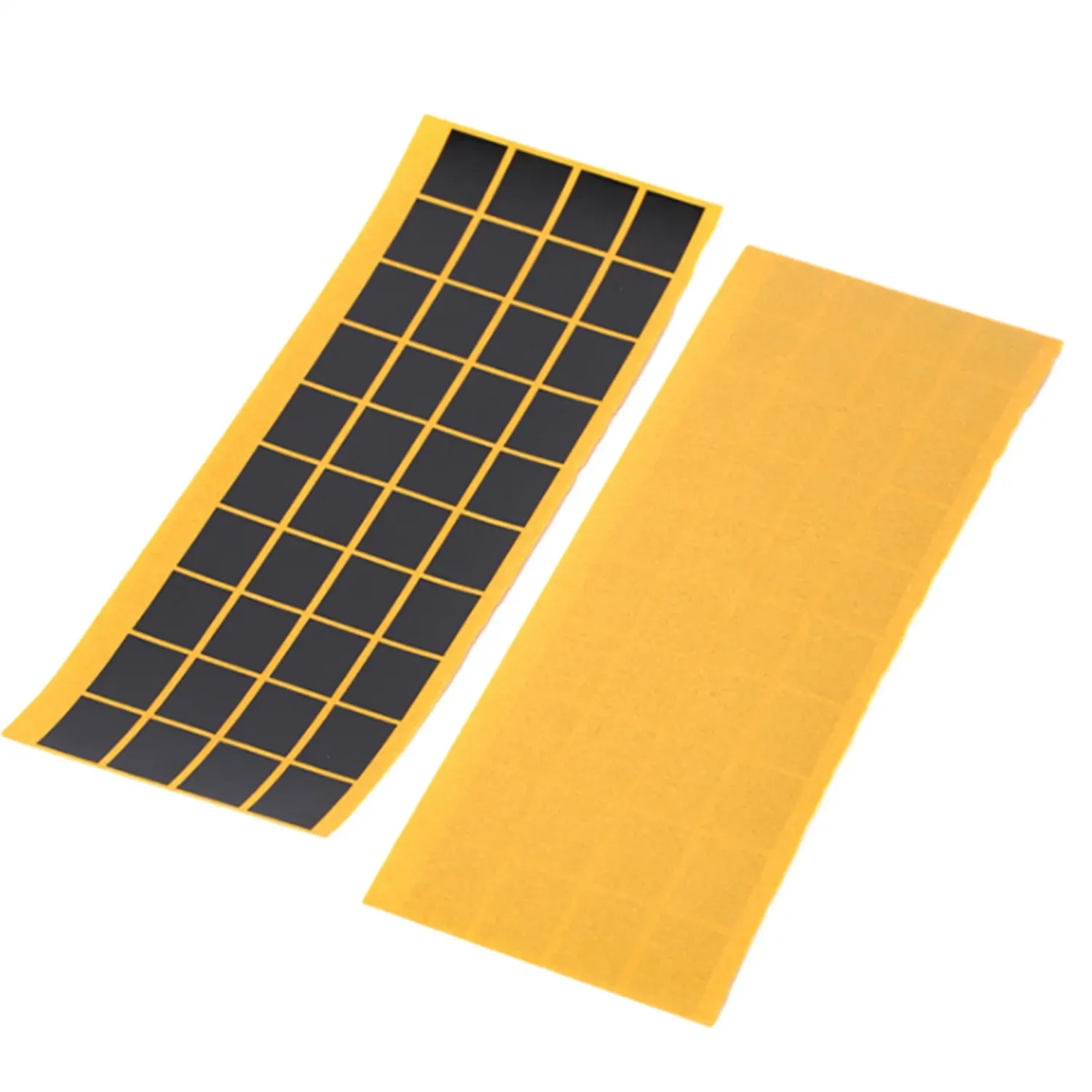

Graphite sheets are thin layers of carbon material, produced from natural or synthetic graphite. They possess a unique combination of thermal, electrical, and mechanical properties, making them suitable for various demanding applications. The structure of graphite sheets allows for excellent flexibility, making them easy to shape and adapt to different environments.

Key Properties of Graphite Sheets

Thermal Conductivity

Graphite sheets are known for their superior thermal conductivity, which makes them ideal for heat dissipation applications in electronics and other high-heat environments.

Electrical Conductivity

Due to their conductive nature, graphite sheets are widely used in electrical applications, including batteries, fuel cells, and conductive coatings.

Mechanical Strength

Despite being lightweight, graphite sheets exhibit high mechanical strength, providing durability and resistance to mechanical stress and deformation.

Chemical Resistance

Graphite sheets are highly resistant to chemical corrosion, making them suitable for use in harsh chemical environments and protective barriers.

Flexibility and Adaptability

Their ability to be easily shaped and adapted makes graphite sheets versatile in various applications, from industrial uses to intricate electronic components.

Top 10 Uses of Graphite Sheets

Electronics

Thermal Management in Devices

Graphite sheets are commonly used in the electronics industry for thermal management. They help dissipate heat in devices such as smartphones, laptops, and other electronic gadgets, preventing overheating and enhancing performance.

EMI Shielding

Graphite sheets are also used for electromagnetic interference (EMI) shielding, protecting electronic devices from unwanted electromagnetic radiation that can cause malfunction or interference.

Energy Storage

Batteries and Supercapacitors

In energy storage systems like batteries and supercapacitors, graphite sheets play a crucial role in enhancing performance and efficiency. Their conductive properties improve energy transfer and storage, leading to longer battery life and faster charging times.

Fuel Cells

Graphite sheets are used in fuel cells to provide efficient conductive pathways, improving the overall efficiency and performance of these energy conversion devices.

Automotive

Heat Management

In automotive applications, graphite sheets are used for their thermal properties. They help manage heat in various components, such as engine parts and electronic control units, ensuring optimal performance and longevity.

Battery Technology

With the rise of electric vehicles (EVs), graphite sheets are becoming increasingly important in automotive battery technology. They enhance the conductivity and efficiency of EV batteries, contributing to longer ranges and faster charging.

Aerospace

Lightweight Components

The aerospace industry benefits from graphite sheets' lightweight and strong characteristics. They are used in various components to improve fuel efficiency and performance, including structural parts and thermal management systems.

Thermal Protection Systems

Graphite sheets are used in thermal protection systems for spacecraft and high-speed aircraft, providing insulation and protecting against extreme temperatures during flight and re-entry.

Industrial Applications

High-Temperature Insulation

Industries utilize graphite sheets in high-temperature settings, such as furnace linings and insulation materials, due to their heat resistance and durability.

Seals and Gaskets

Graphite sheets are used to manufacture seals and gaskets for industrial equipment, providing excellent chemical resistance and high-temperature stability.

Construction

Fireproofing

Graphite sheets are employed in construction for fireproofing applications. Their thermal resistance makes them suitable for use in building materials and fire protection systems, enhancing safety and compliance with fire safety regulations.

Structural Reinforcement

In construction, graphite sheets can be used for structural reinforcement. Their strength and flexibility provide added durability to building materials, improving overall structural integrity.

Medical Devices

Heat Dissipation in Medical Equipment

Graphite sheets are used in medical devices to manage heat, ensuring that equipment operates within safe temperature ranges. This is particularly important in imaging and diagnostic machines, where precision and reliability are critical.

Conductive Pathways in Biomedical Sensors

Graphite sheets are also used in biomedical sensors, providing conductive pathways that enhance the performance and accuracy of these devices.

Renewable Energy

Solar Panels

In renewable energy applications, graphite sheets are used in solar panels to improve thermal management and efficiency. They help dissipate heat generated during energy conversion, enhancing the overall performance of solar cells.

Wind Turbine Components

Graphite sheets are used in wind turbine components for their strength and durability. They help improve the efficiency and lifespan of turbines, contributing to more reliable and sustainable energy production.

Consumer Electronics

Wearable Devices

Graphite sheets are increasingly used in wearable devices for their flexibility and conductivity. They enhance the performance of smartwatches, fitness trackers, and other wearable electronics by managing heat and providing efficient conductive pathways.

Flexible Displays

In the development of flexible displays, graphite sheets provide the necessary conductivity and flexibility, enabling the creation of innovative and adaptable electronic screens.

Telecommunications

Cooling Systems for Network Equipment

In telecommunications, graphite sheets are used in cooling systems for network equipment. They help manage heat in servers, routers, and other critical infrastructure, ensuring reliable operation and preventing overheating.

Antenna Components

Graphite sheets are used in antenna components to provide lightweight and efficient conductive materials, improving signal strength and transmission efficiency.

Conclusion

Graphite sheets are a vital component in many modern technologies and industries, offering unparalleled thermal and electrical conductivity, mechanical strength, and chemical resistance. Their versatility and adaptability make them indispensable in applications ranging from electronics to aerospace. As technology advances, the role of graphite sheets is expected to grow, driven by innovation and a focus on sustainability. By understanding their properties, applications, and proper handling techniques, we can maximize the benefits of this remarkable material.