Contact Us

Solar Street Lights: A Thermal Management Solution

Heat is the primary adversary of LED longevity in solar street lights. As the industry pushes for higher lumens and slimmer designs, effective thermal management ceases to be an option—it is the fundamental requirement for ensuring product lifespan and reliability.

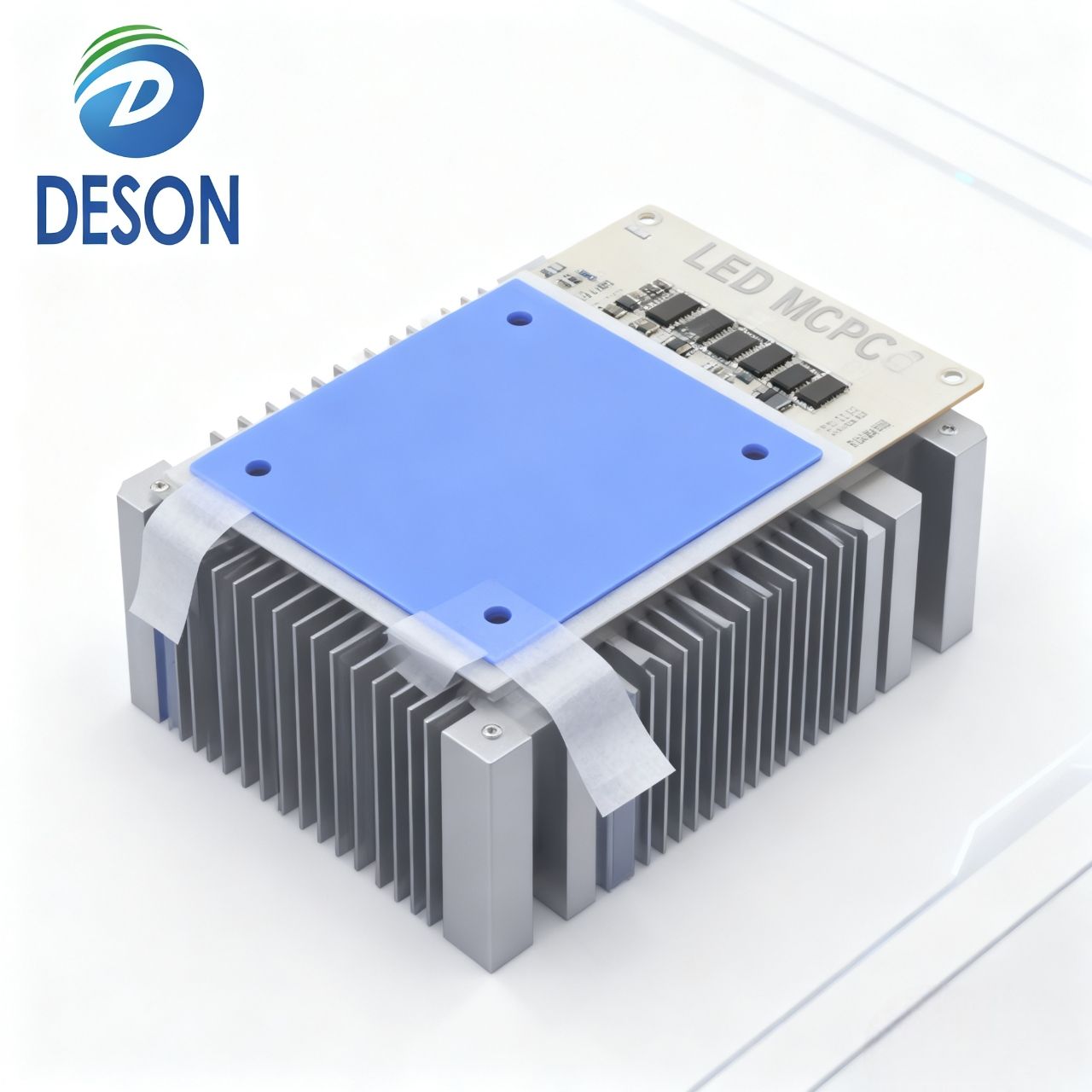

1. The Primary Heat Highway: Thermal Conductive Pads

The first and most critical step in thermal management is efficiently moving heat away from the LED chip. Traditional thermal greases can be messy and inconsistent. Thermal Conductive Pads offer a superior, clean, and reliable solution.

Application: Placed between the LED MCPCB (Metal Core Printed Circuit Board) and the heat sink.

Benefit: These pads fill microscopic air gaps and imperfections on surfaces, eliminating thermal insulation points. By providing a consistent, low-thermal-resistance path, they ensure heat is rapidly transferred from the LED source into the main heat sink structure, where it can be dissipated. This directly translates to a lower junction temperature and a longer LED lifespan.

2. Secure Attachment, Efficient Conduction: Thermal Tapes

For components that require both firm attachment and thermal conduction, Thermal Tapes (thermally conductive adhesive tapes) are the ideal choice.

Application: Bonding smaller heat sinks to driver ICs or other power components within the sealed LED module.

Benefit: They provide a robust mechanical bond while simultaneously sinking heat, eliminating the need for mechanical fasteners that can compromise ingress protection (IP rating). This simplifies assembly and ensures critical components within the module remain cool.

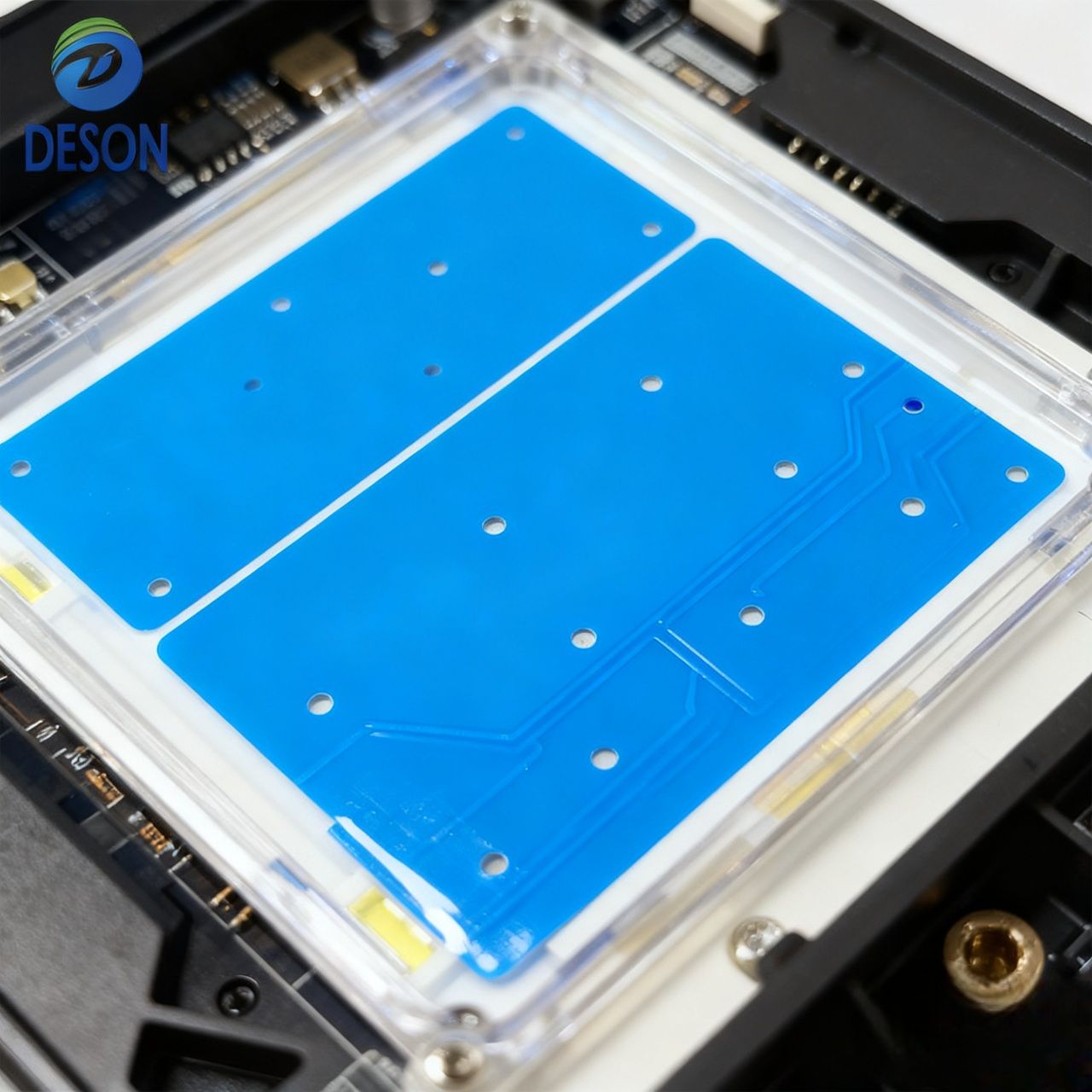

3. Essential Safety and Isolation: Polypropylene/Polycarbonate Insulators

Safety and electrical integrity are non-negotiable. When the heat sink is part of the external fixture and accessible, electrical isolation is mandatory. Polypropylene and Polycarbonate Insulators are designed for this critical role.

Application: Placed between a live MCPCB and the grounded aluminum heat sink/housing.

Benefit: These films offer excellent dielectric strength, preventing electrical shorts, while still maintaining good thermal conductivity. They act as a protective barrier, ensuring user safety and system reliability without creating a significant thermal bottleneck.

4. Shielding and Sealing: EMI Shield Gaskets & Silicone Foam

Modern LED drivers can generate electromagnetic interference (EMI). Furthermore, the entire assembly must be protected from the elements.

EMI Shield Gaskets: Our conductive elastomer gaskets provide a robust seal against electromagnetic interference, ensuring the LED driver does not disrupt other electronics and complies with EMC regulations.

Silicone Foam (Fire-Retardant): This material is perfect for creating compressible, weather-proof seals for housing covers and joints. Its inherent fire-retardant properties add a crucial layer of safety, preventing the spread of flame—a vital consideration for public infrastructure.

5. The Ultimate Thermal Barrier for Extreme Environments: Aerogel

In regions with extreme ambient temperatures, preventing external heat from radiating onto the LED module during the day can be as important as dissipating internal heat at night.

Application: As an external insulation layer on the inner surface of the fixture housing or within the pole itself.

Benefit: Aerogel is one of the world's best insulating materials. By incorporating a thin layer, you can significantly reduce the solar thermal load on the fixture, keeping the internal components closer to ambient temperature. This gives the primary heat sink a much easier task when the lights turn on, enhancing overall system efficiency in harsh climates.

Conclusion:

Last but not least, Deson's products can solve any specific challenge. Together, they form a synergistic ecosystem for thermal mastery:

Heat is efficiently pulled from the LED via the Thermal Conductive Pad, safely passing through a Polypropylene Insulator to the main heat sink. Critical driver components are kept cool with Thermal Tape. The entire assembly is shielded from EMI and sealed against moisture and dust with EMI Gaskets and Silicone Foam, while Aerogel provides an external defense against solar gain.

Don't let heat shorten the life and dim the future of your solar lighting projects. By integrating Deson's comprehensive thermal management solutions, you are not just adding components—you are engineering a product built for reliability, efficiency, and maximum longevity.